How to Extend Cloth Life By Cleaning

Proper care and maintenance of filter cloths are very important to the performance of the filter press.

During filtration, the filter cloth is the initial barrier that separates solids from liquid, therefore, the filter cloth must remain porous to provide high filtration rates.

During normal operation, the filter cloth may gradually become plugged with minute particles, such as those from a metal finishing sludge. These particles penetrate the cloth and become lodged in the depth of the weave, which leads to decreased filterability. These particles must be removed periodically to maintain high filtration rates and drier cakes. Oils and excessive flocculation polymers will also blind the cloths.

Filter cloth washing is required when one of the following factors indicate plugging has occurred.

Initial high filtration pressure.

Long filtration cycles.

Wet filter cakes.

CGR Plates

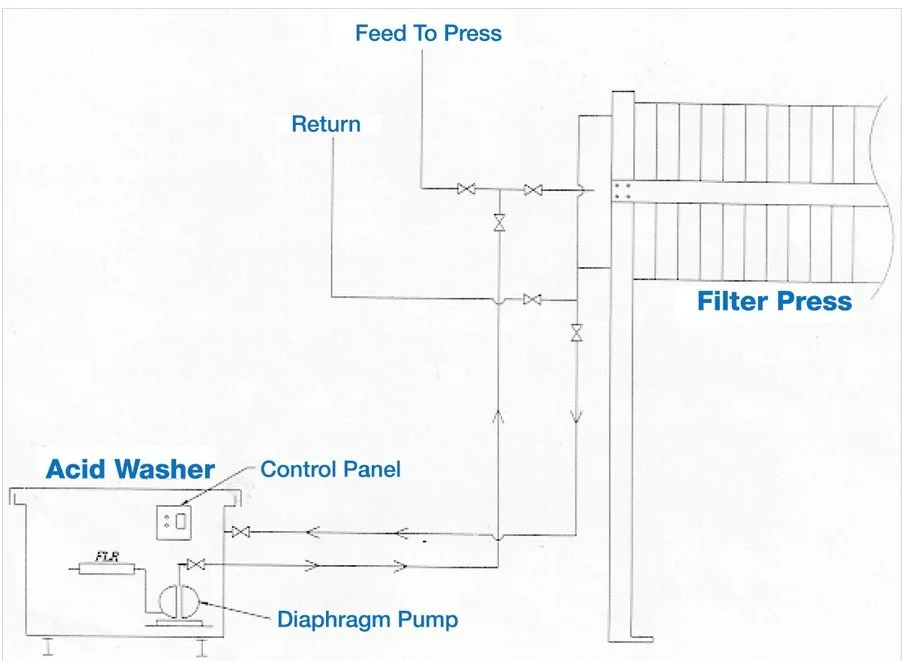

There are several methods used to wash cloths while they are still installed in the press. The most commonly used method with metal finishing sludge is acid washing which requires the following:

Acid storage tank of sufficient capacity to fill press and allow for recirculation, approximately 1.5 x holding capacity of press (7.5 gallons per cubic foot).

A 25% solution of hydrochloric (muriatic) acid. A lower or higher concentration may be necessary due to solubility levels of entrapped particles. Note: Extreme care must be taken when handling acid.

Low pressure (20-30 PSI max.) Acid resistant pump.

Necessary plumbing (hoses or rigid PVC pipe) to isolate the press from the sludge stream and allow for both recirculation to the acid storage tank and final draining of the spent acid solution. A throttling valve installed in the return line to the acid tank may be necessary to insure complete top to bottom press filling and washing of the cloths.

Method

Clean all filter cloths of all sludge cake with nylon spatulas.

Close filter press.

Disconnect sludge feed line from sludge pump.

Connect outlet of acid pump to sludge feed line to filter press.

Connect lower outlet of filter press to acid recirculation tank.

Open acid feed line to filter press.

Start acid feed pump. It will take considerable time to fill all of the chambers of the filter press before the acid will return to storage tank. continually inspect filter press for leakage during filling and recirculating.

Allow pump to recirculate for one to two hours.

Turn off acid feed pump.

Follow air blowdown sequence in operation instructions to purge acid from filter press (use maximum 15 PSI air).

Disconnect acid feed system and reinstall sludge pump and outlet lines..

Non-gasketed Plates

Acid washing as described above is not recommended on non-gasketed type filters unless extra precautions are taken to contain the leakage between plates.

You can also acid “dip” wash the plates and/or cloths by immersing them in a tank of acid. The immersion method though is less efficient than thru washing in the press and will probably require at least an overnight soaking to clean out the depth of the weave. Another slight problem, if the plates are dipped, is that the plates are lighter than water and will float, so some method of keeping them submerged must be used.

Another method used for cloth washing is a portable high pressure (800-1200 PSI at 2-10 GPM) cold water spray unit. These units come with a hand held power wand with spray nozzle which is slowly moved over the cloths. They clean by not only flushing off the cloth surfaces but by also penetrating the cloth to flush particles out of the depth of the weave.